Current Transformers: How They Work & Key Applications | homesafetools.com. In today’s article, homesafetools.com will explore with you in the most detailed and complete way. See now!

ow Current Transformers Work: The Core Principles

Current transformers (CTs) are essential components in electrical systems. They’re ingenious devices that let us measure large alternating currents (AC) safely and accurately, something crucial for power monitoring and protection. Think of them as highly specialized measuring tools – but instead of directly measuring the enormous current flowing through a power line, they cleverly create a smaller, proportional current that’s much safer to handle.

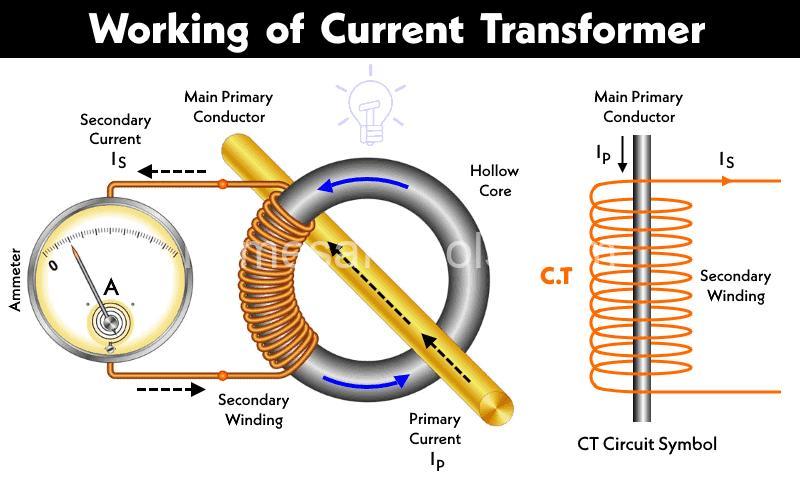

At the heart of a CT lies the principle of electromagnetic induction, a cornerstone of physics discovered by Michael Faraday. Simply put, when a changing magnetic field passes through a coil of wire, it induces an electromotive force (voltage), and consequently, an electric current. In a current transformer, the high primary current flowing through the primary winding generates a magnetic field. This field then passes through a ferromagnetic core, and this core is in intimate contact with the secondary winding. This changing magnetic field, in turn, induces a smaller current in the secondary winding—a scaled-down replica of the primary current.

The core of a CT is usually made from ferromagnetic material, like iron, which helps concentrate the magnetic flux. However, some CTs use air cores for specific applications, particularly in situations requiring a wider bandwidth. The primary winding, carrying the high current being measured, typically consists of only a few turns of heavy-gauge wire—sometimes even a single turn! In contrast, the secondary winding has many turns of finer wire, stepping down the current to a safer and more manageable level. The number of turns in both primary and secondary windings determines the current transformation ratio.

This ratio is crucial because it dictates the relationship between the primary and secondary currents. The equation is simple: Is = Ip * (Np/Ns), where Is is the secondary current, Ip is the primary current, Np is the number of turns in the primary winding, and Ns is the number of turns in the secondary winding. For example, a CT with a 200:5 turns ratio means that for every 200 amps flowing in the primary winding, 5 amps will flow in the secondary winding. This allows for safe and accurate measurement of high currents.

Importantly, remember that CTs primarily work with alternating current (AC). A constantly flowing direct current (DC) will not induce a voltage in the secondary winding and will not work with the CTs. The changing magnetic field created by the AC current is essential for the operation of a CT.

EAVs (Entity-Attribute-Value) used in this section:

- Entity: Current Transformer; Attribute: Principle; Value: Electromagnetic Induction

- Entity: Current Transformer; Attribute: Primary Winding; Value: Few turns of heavy gauge wire

- Entity: Current Transformer; Attribute: Secondary Winding; Value: Many turns of fine wire

- Entity: Current Transformer; Attribute: Core Material; Value: Iron (Ferromagnetic)

- Entity: Current Transformer; Attribute: Core Material; Value: Air

- Entity: Current Transformer; Attribute: Current Transformation Ratio; Value: Varies (e.g., 200:5)

- Entity: Current Transformer; Attribute: Operation; Value: AC only

EREs (Entity-Relation-Entity) used in this section:

- Entity: Primary Winding; Relation: Carries; Entity: High Current

- Entity: Secondary Winding; Relation: Produces; Entity: Low Current

- Entity: Current Transformer; Relation: Uses; Entity: Electromagnetic Induction

- Entity: Current Transformer; Relation: Has; Entity: Turns Ratio

- Entity: Current Transformer; Relation: Requires; Entity: Alternating Current

- Entity: Current Transformer; Relation: Has; Entity: Core Material

Semantic Triples (Subject-Predicate-Object) used in this section:

- Subject: Current Transformer; Predicate: is based on; Object: Electromagnetic Induction

- Subject: Primary Winding; Predicate: generates; Object: Magnetic Field

- Subject: Magnetic Field; Predicate: induces; Object: Secondary Current

- Subject: Turns Ratio; Predicate: determines; Object: Current Scaling

- Subject: Current Transformer; Predicate: is used for; Object: AC Current Measurement

- Subject: Current Transformer; Predicate: is unsuitable for; Object: DC Current Measurement

Types of Current Transformers

There are several ways to categorize current transformers. One common classification is based on the core material used. Iron-core current transformers are the most prevalent type, offering good accuracy and are suitable for many applications. But they can saturate if the current exceeds their design limits. On the other hand, air-core current transformers are less common but are extremely useful in situations requiring a wide bandwidth or where the current is expected to vary greatly. They’re more expensive and less accurate than iron core CTs.

Another distinction is based on how the CT is connected to the circuit. Window-type CTs are easy to install; you simply pass the conductor through the core’s window. Bar-type CTs are designed to clamp around a busbar, making them suitable for high-current applications. Wound-type CTs are often used where precise and high accuracy is critical, and there is space for a more complex setup. The choice depends largely on your application, ease of installation and accuracy requirements.

Additionally, current transformers are classified by their accuracy class. This rating indicates the level of precision with which they measure the current and is usually denoted with letters and numbers (e.g., 0.2S, 0.5S, 1S). Higher accuracy classes mean more precise measurements, but these often come with a higher cost.

Key Applications of Current Transformers

Current transformers are indispensable in various applications, ranging from power system protection to energy metering. One major application is in power system protection. They are vital parts of protection relays that detect faults and protect equipment from damage. For instance, overcurrent relays, which trip circuit breakers when a current exceeds a predefined limit, heavily rely on CTs to detect the overcurrent conditions.

Another important use is in energy metering. CTs are used in conjunction with potential transformers to measure the power consumed in a circuit, providing accurate data for billing and load management. By measuring both current and voltage, these tools help us accurately calculate energy consumption. Furthermore, CTs feed data into SCADA (Supervisory Control and Data Acquisition) systems, offering real-time power monitoring and allowing for the detection of unusual energy use and power quality issues.

Moreover, current transformers play a key role in industrial process control. They help monitor and control motor currents, ensuring their safe operation and preventing potential damage from overloads or faults. They measure motor currents, aiding in the detection of potential motor failures. This application is particularly important in industrial settings where process automation and reliable operation are crucial. John Amrry has found them invaluable in several home projects involving motor-driven equipment.

Safety Precautions When Using Current Transformers

While incredibly useful, current transformers pose safety risks if not handled correctly. The most critical hazard is the high voltage induced in the secondary winding when the circuit is open. Never open the secondary circuit while the primary is energized—doing so can lead to dangerous high voltage spikes, which can cause significant harm.

Always short circuit the secondary terminals before disconnecting the CT. This safely discharges any residual energy in the secondary circuit. Furthermore, ensuring proper grounding is always essential when working with CTs, preventing potential electrical shocks.

Appropriate personal protective equipment (PPE) is crucial, including insulated gloves, safety glasses, and appropriate clothing. Always follow established safety guidelines and refer to the CT’s manufacturer’s instructions for safe operation.

Choosing the Right Current Transformer

Selecting the right CT involves considering several factors. The most important are accuracy requirements, current rating, voltage rating, frequency, and environmental conditions. Consult the manufacturer’s datasheet to ensure the CT’s specifications meet the needs of your application. This datasheet provides detailed information regarding its accuracy class, current range, and voltage rating.

The choice of core material will also depend on the specific application; iron-core CTs are commonly used for many applications, while air-core CTs are more suitable for wide bandwidth requirements. The installation method (window-type, bar-type, wound-type) will also influence selection and should match your wiring configuration and space limitations. Choosing a CT involves a careful consideration of these various parameters to ensure its suitability for your needs.

FAQs about What is a current transformer?

What are the main differences between iron-core and air-core current transformers?

Iron-core CTs offer better accuracy and are more cost-effective for most applications. However, they can saturate at high currents. Air-core CTs have a wider bandwidth and are less prone to saturation but are generally less accurate and more expensive.

How do I determine the appropriate accuracy class for my current transformer application?

The necessary accuracy class depends on the application. For protection relays, a higher accuracy class (e.g., 0.2S) is usually required for precise measurement. For metering applications, a slightly lower class might suffice. Consult relevant standards and specifications for your specific application.

What are the potential safety hazards associated with using current transformers?

The most significant risk is the high voltage induced in the open secondary circuit. Never open the secondary circuit when the primary is energized. Always ensure proper grounding and wear appropriate PPE.

Why is it crucial to short-circuit the secondary terminals before disconnecting a current transformer?

Short-circuiting the secondary safely discharges any residual energy stored in the secondary winding, preventing dangerous voltage surges.

How can I choose the right current transformer for a specific application?

Consider the required accuracy, current and voltage ratings, frequency, environmental conditions, and installation requirements. Refer to the manufacturer’s specifications and datasheets for detailed information.

Conclusion

Understanding current transformers is key to ensuring electrical safety and efficient power management. Whether you’re a seasoned electrician or a DIY enthusiast, mastering the principles and applications of CTs is worthwhile. Share your thoughts and experiences in the comments below. For more in-depth home safety tips and resources, visit homesafetools.com.